TECHNICAL SPECIFICATIONS

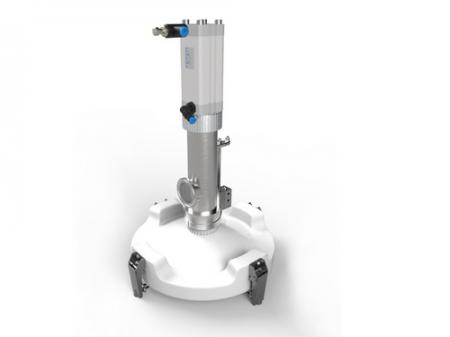

- This is a volumetric filling machine that works with FESTO pneumatic system.

- Easy to adjust and record the filling range by the numerator and the hand wheels.

- It primes the product from its 80 liters 316 L seamless stainless steel hopper.

- High surface smoothness and argon arc welding technology prevents contamination.

- The seals are manufactured from teflon, viton or polyethylene according to the product to be filled.

- The parts on the machine are connected by tri –clamps.

- The nozzle, the main valve and the filling piston are designed for an easy-cleaning .They can be dismantled easily without using any tool.

- Interchangeable nozzles are available according the product, either it's liquid, viscous or particulated.

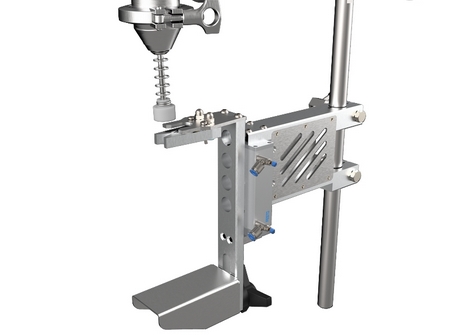

- There is a heigth adjustable platform on the filler to place the packages during the filling process.

- The machine stands on a stainless steel frame which is supprted by 4 castors, it can be easily move to anywhere.

- The machine can be considerated as exproof system as it only uses compressed air to function.

- The detailed instruction manual for each model is available.

MATERIALS USED ON THE FILLER

- The parts that contact with the product are 316 L stainless steel. The other parts are 304 L stainless steel and anodized aluminium.

- FESTO Pneumatic Equipments. (Oil-free)

- A table top version is available suitable for small filling areas mostly.

OPERATING TEMPERATURE :

From +5 ºC to +85 ºC with standard sealings.

Above 90 ºC with special sealing.

FILLING ACCURACY : ± %1

TYPES OF FILLED PRODUCTS: Cosmetic Creams, Nail Polish, Mascara, Vaseline, Shampoo, Honey, Oils, Jam, Chocolate Speard, Cream Cheese, Sauce, etc.

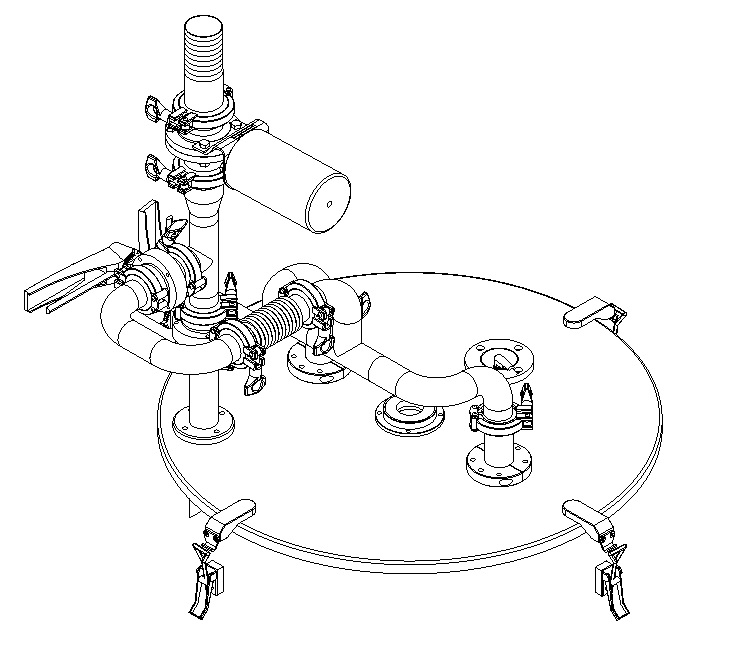

Connection Part

This connecting equipment can be used to connect the machine directly to the storage tank.

CIP Suitable Cleaning System

This option is used once the machine will be cleaned using a CIP system. All the components are compatible with the use of CIP cleaning agent.

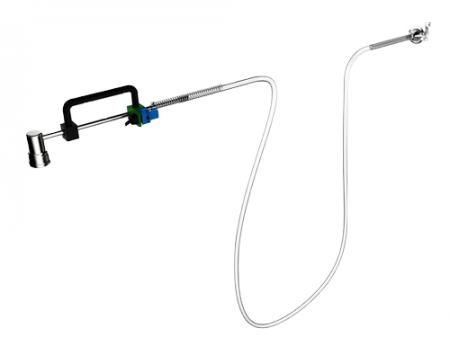

SN025 Filling Nozzle

This flexible nozzle is used to fill liquid dairy products.

SN093 Filling Nozzle

Decoration nozzle for pies and cake decoration.

SN053 Filling Nozzle for Products with Particles

Flexible Nozzle for Liquid and Particulated Products

Spout Pouch Filling Mechanism

Spout Pouch Filling Mechanism is used to fill the products into doypack type packages.

SN065 Filling Nozzle

This nozzle is used for the products like honey, chocolate cream especially to prevent dripping.

SN01 Filling Nozzle

This filling nozzle is used to fill liquid and viscous products up to 150ml.

VNS09 Filling Nozzle for Products with Particles

VNS09 Filling Nozzle is used for products with particles most of the time.

SN02 Filling Nozzle

This filling nozzle is used to fill liquid and viscous products starting from 100ml.

Level Detecting System

This level detecting system is designed to detect the level of the product on the hopper, and to start/stop the transfer pump automatically.

Backside Cleaning System

It is designed to clean the back side of the sealing system for sticky products.

Double Jacketed Hopper

The double jacketed hoppers are designed for keeping the products at a certain temperature during the filling process.

Agitator

The Agitator is used for keeping the products homogeneous in the hopper, or spreading the temperature homogeneously to the product in case of using the double jacketed hopper.

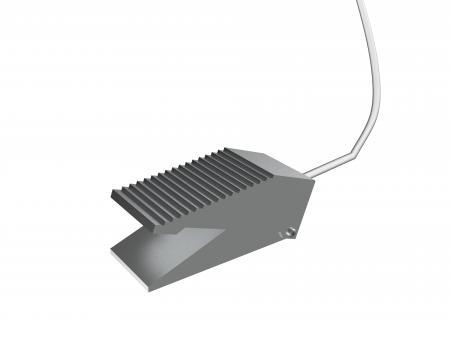

Foot Pedal

Foot Pedal

Additional Filling Cylinder

This interchangeable piston enables you to fill smaller volumes than the machine standard.