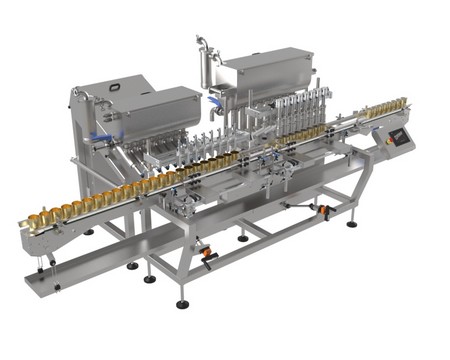

· FILLS 2 DIFFERENT PRODUCTS INTO A SINGLE PACKAGE WITH A CONSTANT RATIO

. VINEGAR-OIL, SAUCE-OIL, BALSAMIC-OIL, LEMON JUICE-OIL, ETC

. VOLUMETRIC FILLING SYSTEM

· CAPACITY: 4800 PACKAGES PER HOUR

· FILLING ACCURACY: ± 1%

. ANTI DROPPING SYSTEM ON THE FILLING NOZZLES

· VARIOUS PACKAGING SIZES AND SHAPES

· HOT AND COLD FILLING

. COMPATIBLE TO THE FOOD HYGIENE STANDARDS

For the two component filling machines, the capacity varies according to the filling range as below (specified according to the maximum filling range):

| Model | First Product's Filling Range |

Second Product's Filling Range |

Capacity |

| VD50-4 FOT / VD10-4 FOT | 5ml - 50 ml | 2ml - 10 ml | 4000 |

| VD500-6 OT / VD150-6 OT | 50ml - 500ml | 15ml - 150ml | 3000 |

| PDD200-8 OTA / PDD50-8 OTA | 20ml - 200ml | 5ml - 50ml | 4800 |

TECHNICAL SPECIFICATIONS

- Includes two separate filling systems for each component, with separate filling adjustments.

- Primes the products from two seperate hoppers with an automatic level control system.

- The level control system is synchronized with the transfer pump to start or stop.

- All the parts including the main valve and the nozzles are connected by tri-clamps for an easy disassembling for the cleaning process.

- The volume adjustment can be done by a handwheel and a numerator on the machines for each products.

- There are interchangable filling nozzles which are designed for liquids and viscous products, with an anti dropping system.

- Adjustable speed diving nozzle for foamy products.

- No container-No fill System.

- User friendly touch screen interface available in different languages.

- 4 meters convoyer with adjustable side rails for various sizes of packages.

- The working system is pneumatic an electronic. It operates with 6 bars compressed air.

- The consumption of air is 800 lt/minute when it’s performing with the maximum volume and the maximum speed.

- The electrical connection is three phase (380v / 50-60 Hz)

- Optional C.I.P. suitable cleaning system.

- Optional Double Jacketed Hopper.

- Optional Agitator.

- Optional Filling Piston Back Side Cleaning System.

MATERIALS USED ON THE FILLER

- The parts that contact with the product are 316 L stainless steel. The other parts are 304 L stainless steel and anodized aluminium.

- FESTO Pneumatic Equipments. (Oil-free)

- OMRON PLC, Touch Screen & Drivers.

- SICK Photocells.

OPERATING TEMPERATURE

From +5 ºC to +85 ºC with standard sealings.

Above 90 ºC with special sealing.

FILLING ACCURACY : ± %1

TYPES OF FILLED PRODUCTS:

Vinegar-Oil, Sauce-Oil, Balsamic-Oil, Lemon Juice-Oil, Yogurt-Jam, etc.