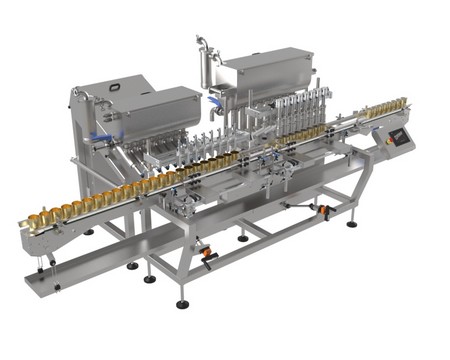

· VOLUMETRIC FILLING SYSTEM

· LIQUIDS, SEMI LIQUIDS, VISCOUS & PRODUCTS WITH PARTICULES

· CAPACITY: 840 - 1600 PACKAGES PER HOUR

· FILLING ACCURACY: ± 1%

. ANTI DROPPING SYSTEM ON THE FILLING NOZZLES

· VARIOUS PACKAGING SIZES AND SHAPES

· HOT AND COLD FILLING

. COMPATIBLE TO THE FOOD HYGIENE STANDARDS

For the two heads filling machines, the capacity varies according to the filling ranges as below:

|

Model |

Filling Range |

Capacity |

Working Mode |

|

PVD200-2 OTPAY PDD200-2 OTPAY |

Min. 20 Max. 200ml |

1600 |

Pneumatic |

|

PVD1000-2 OTPAY PDD1000-2 OTPAY |

Min. 100 Max. 1000ml |

1500 |

Pneumatic |

|

PVD2000-2 OTPAY PDD200-2 OTPAY |

Min. 200 Max. 2000ml |

1200 |

Pneumatic |

|

PVD5000-2 OTPAY PDD200-2 OTPAY |

Min. 500 Max. 5000ml |

840 |

Pneumatic |

TECHNICAL SPECIFICATIONS

- Primes the product from a 80 liters hopper with an automatic level control system.

- The level control system is synchronized with the transfer pump to start or stop.

- All the parts including the main valve and the nozzles are connected by tri-clamps for an easy disassembling for the cleaning process.

- The volume adjustment can be done by a handwheel and a numerator on the machine.

- There is one interchangable filling nozzle which is designed for liquids and viscous products, with an anti dropping system.

- Adjustable speed diving nozzle for foamy products.

- No container-No fill System.

- User friendly touch screen interface available in different languages.

- 2 meters convoyer with adjustable side rails for various sizes of packages.

- The working system is pneumatic an electronic. It operates with 6 bars compressed air.

- The consumption of air is 600 lt/minute when it’s performing with the maximum volume and the maximum speed.

- The electrical connection is three phase (380v / 50-60 Hz)

- Optional C.I.P. suitable cleaning system.

- Optional Double Jacketed Hopper.

- Optional Agitator.

- Optional Filling Piston Back Side Cleaning System.

MATERIALS USED ON THE FILLER

- The parts that contact with the product are 316 L stainless steel. The other parts are 304 L stainless steel and anodized aluminium.

- FESTO Pneumatic Equipments. (Oil-free)

- OMRON PLC, Touch Screen & Drivers.

- SICK Photocells.

OPERATING TEMPERATURE

From +5 ºC to +85 ºC with standard sealings.

Above 90 ºC with special sealing.

FILLING ACCURACY : ± %1

TYPES OF FILLED PRODUCTS:

Chocolate Spread, Peanut Butter, Hazelnut Hash, Honey & Cream Honey, Mayonnaise, Ketchup, Mustards, Sauces, Jam & Marmelade, Tomato Paste, Pepper Paste, Cream Cheese, Cheese Spread, Labne, Yogurt, Milk, Ayran, Clotted Milk, Molasses, Vinegar, Balsamic Vinegar, Syrups, Pomgrenade Concentrate, Edible Oils, Pre-cooked Meals, American Salad, Mashed Vegetables, Tapenade, Glaze, Toppings, Soups, Cake and Dough, etc.

Cosmetic Oils, Cosmetic Creams, Shampoo, Conditionner, Liquid Soap, Bodywash, Hair Cream, Body Lotion, Peelings, Face and Body Mask, Waxes, Gels, Vaseline (Petroleum Jelly), Foundation, BB Cream, etc.

Ointments, Lotions, Glycerin, Desinfectant, biomedical and sanitary products, veterinary products, etc.

Paints, Glue (PVA), Hydrogen peroxide, ink, Fertilizers, Pesticides, Varnish, Household Product, Engine Oil, Glass cleaner, Anti-Freeze, etc.