TECHNICAL SPECIFICATIONS

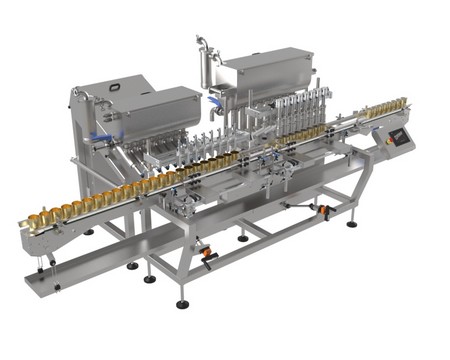

- Feeds the paste to the filling cylinder by the help of the in-feed screw.

- All the parts including the main valve and the nozzles are connected by tri-clamps for an easy disassembling for the cleaning process.

- The volume adjustment can be done by a handwheel and a numerator on the machine.

- No container-No fill System.

- User friendly touch screen interface available in different languages.

- 2 meters convoyer with adjustable side rails for various sizes of packages.

- The working system is pneumatic an electronic. It operates with 6 bars compressed air.

- The consumption of air is 800 lt/minute when it’s performing with the maximum volume and the maximum speed.

- The electrical connection is three phase (380v / 50-60 Hz)

- An agitator is included into the hopper.

MATERIALS USED ON THE FILLER

- The parts that contact with the product are 316 L stainless steel. The other parts are 304 L stainless steel and anodized aluminium.

- FESTO Pneumatic Equipments. (Oil-free)

- OMRON PLC, Touch Screen & Drivers.

- SICK Photocells.

OPERATING TEMPERATURE

From +5 ºC to +85 ºC with standard sealings.

FILLING ACCURACY : ± %1

TYPES OF FILLED PRODUCTS:

Hazelnut Paste, Hazelnut Butter, Pistachio Paste, Almond Paste, Peannut Paste, Date Paste, etc.

Moroccan Soap (Black Soap)